In the realm of building, production, and DIY projects, fasteners and bolts play a critical role as essential components. These seemingly simple components are instrumental to the assembly of countless buildings and devices. Understanding the development of fasteners and screws not only highlights their significance in contemporary engineering but additionally uncovers the complex designs and innovations that have appeared over time. From their initial iterations to the present day's varied array of unique fasteners, the journey of nuts and bolts is a captivating testament of mankind's ingenuity and utility.

While we dig deeper into this subject, we will explore the various types of nuts and screws, their specific uses, and important factors to consider when choosing the right fastener for your task. Whether a experienced professional or a DIY enthusiast, having a comprehensive understanding of various fasteners can make a notable impact in the success and durability of your projects. Come us as we travel through the nuances of fasteners, screws, and the related components, providing you with the information needed to take wise choices for your upcoming project.

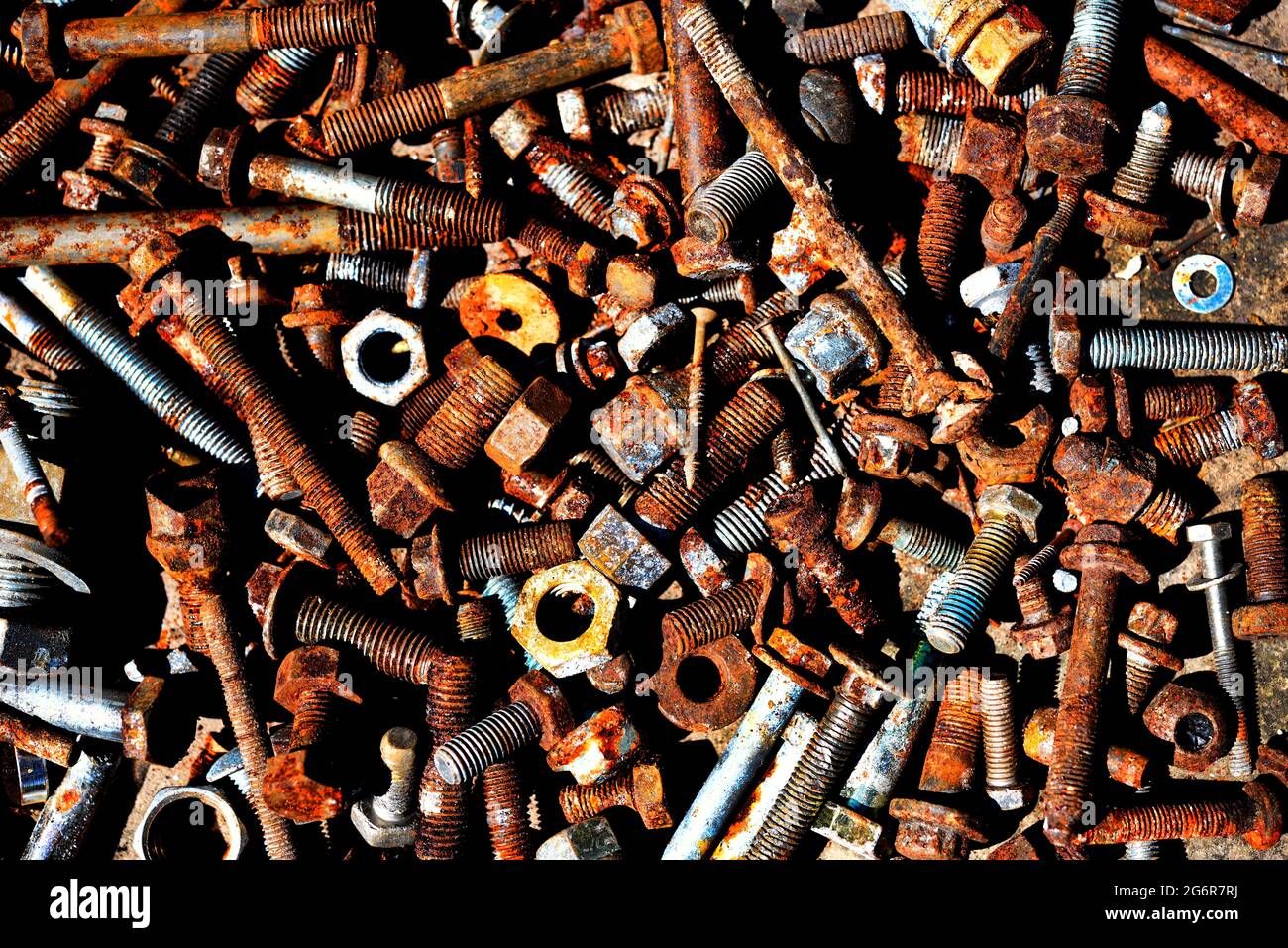

Types of Nuts and Bolts

Fasteners are crucial components used in multiple applications, each designed to serve specific purposes. Bolts and Nuts Store used type of fastener is the hex bolt, noted for its hex head, making it easier to tighten and loosen with a wrench. Another frequently used choice is the carriage fastener, having a circular head and a quadrate neck that prevents the bolt from turning after installation. Lag screws, also known as lag fasteners, are specially designed for heavy applications, offering a strong hold in timber and other materials.

Fasteners also come in different types, each tailored for particular uses. Regular hex nuts are commonly utilized and compatible with various types of bolts, while lock nuts are designed to resist loosening due to vibration. Washer nuts, featuring a built-in washer, spread the load over a larger area and minimize the risk of harm to the material. Understanding these various types helps in choosing the appropriate connector for a project, guaranteeing a safe and durable connection.

For specific needs, unique fasteners are available, such as nylon lock nuts that provide an added layer of safety by preventing the movement of threads. Additionally, security fasteners, like tamper-proof nuts and bolts, are crucial in applications where access by unauthorized individuals is a concern. By learning with the different kinds of fasteners, you can make educated choices that improve the effectiveness of your construction or fixing tasks.

Materials and Coatings

The substances used in nuts and bolts have a critical role in assessing their strength, longevity, and appropriateness for various purposes. Steel is the most common material thanks to its elevated tensile strength and adaptability. It’s often used in structural and automotive applications. For environments dealing with moisture or corrosive elements, corrosion-resistant steel is favored for its protection to rust and corrosion, making it ideal for external projects. Copper alloy and titanium are also used, with copper alloy being efficient in electrical connections due to its ability to conduct electricity, while titanium offers a high strength-to-weight ratio, making it widely used in aviation and high-performance contexts.

Finishes are of equal importance as they enhance the efficacy and lifespan of fasteners. Zinc plating, for case, provides a barrier against rust and is frequently found on bolts used in environments where moisture is available. Galvanized fasteners, which undergo a enhanced coating process, offer enhanced corrosion resistance, making them ideal for heavy-duty outdoor applications. Additionally, powder finish can provide both aesthetic appeal and functional protection against wear and corrosion.

Choosing the appropriate material and coating is essential for maximizing the efficacy of fasteners. Considerations such as the working environment, load requirements, and chemical exposure must be considered. For example, choosing coatings that resist corrosion like PTFE or nylon can significantly increase longevity in harsh conditions, while choosing a particular material can ensure the fasteners can handle the required pressure and weight loads in their planned applications.

Specialized Fasteners

Specialized fasteners act a vital role in multiple applications where standard nuts and bolts may not suffice. For example, tamper-proof fasteners are created to stop unauthorized access or removal, making them perfect for security-sensitive installations. These distinct nuts and bolts often demand specific tools for installation and removal, adding an additional layer of security in environments where safety is a priority.

Another notable category is anchor bolts, which are essential in construction for securing structures to concrete foundations. They offer stability and strength, especially in heavy-duty projects. When selecting anchor bolts, it is important to consider factors such as the type of load they will bear and the environment in which they will be used, ensuring that they provide the needed support for durable performance.

In addition to security and construction applications, there are also special fasteners like nylon lock nuts. These nuts feature a nylon insert that secures the nut in place, preventing it from loosening due to vibration or movement. Their distinct characteristics make them suitable for various machinery and automotive repairs where keeping tight connections is crucial for operational safety and efficiency.